Hvlp Spray Gun Air Pressure Setting

Hvlp spray gun air pressure setting. You are now ready to do a test spray out. Using the sprayer gun with the high-pressure setting can split the fan pattern where the pattern in the middle is very light while on the edges they are heavy. This limits bounceback and wasted paint as more paint is likely to stick to the surface that youre painting.

On an HVLP gun this spec is usually found on the gun and is the maximum PSI it can have while still maintaining the maximum 10 lb at the cap for legal HVLP transfer efficiency 68. Setting up and spraying with the Harbor FreightHVLP gun 38308 and the 43430 Pressure AdjustmentOpen your compressor regulator up so there is plenty of air pressure in the line to the gun I set mine to about 90 psi. I spray with either a Binks or Devilbiss cup gun HVLP and I normally have the pressure set around 60 coming out of my filters and regulator in the spray room.

If 45 with gun off works fine then youre fine. In this video I will explain the difference between HVLP Conventional and LVLP Spray Guns and demonstrate the different spray patterns they have and the re. This may result in wastage of material and you will be compromising on the durability of the paint system as well.

Air Pressure and Volume Setting up the volumes and pressures of an HVLP spray gun will involve a lot of trials and errors. Use your fan-control knob located on top of your sprayer for this setting. For starters ensure your spray gun is about six inches high.

Forum Responses Finishing Forum Glad you can appreciate the difference. Continue increasing the air pressure in increments of 5 or 10 psi and spraying short bursts. This changes how far the fluid needle can be pulled back ultimately controlling how.

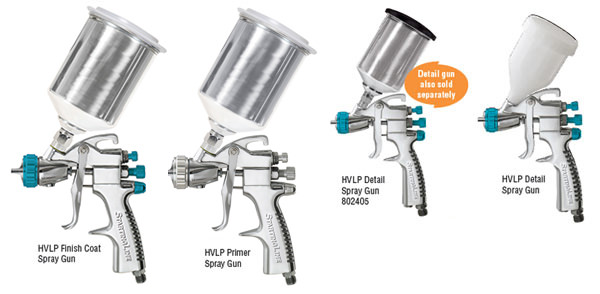

Unlike conventional air spray guns modern HVLP spray guns atomize coatings by using a high volume of air at low air cap pressure generally in the 1 - 10 psi range. While most guns spray paint at around 50 PSI most HVLP guns only spray at around 10 PSI. This inconsistent spray paint pattern can cause streaking.

The paint technical data sheets usually give the recommended pressure at the gun. For non-HVLP guns that pressure is usually between 40 and 60 psig.

On an HVLP gun this spec is usually found on the gun and is the maximum PSI it can have while still maintaining the maximum 10 lb at the cap for legal HVLP transfer efficiency 68.

Increase the air pressure by 5 or 10 psi and spray another burst. On an HVLP gun this spec is usually found on the gun and is the maximum PSI it can have while still maintaining the maximum 10 lb at the cap for legal HVLP transfer efficiency 68. If 45 with gun off works fine then youre fine. The pattern will be a little wider and the dots a little smaller. Set the air pressure at the inlet to the gun to the manufactures specs. This next image is of the location of the fluid control. HVLP high volume low pressure means a high volume of material is displaced at a low pressure of air flow. For starters ensure your spray gun is about six inches high. Setting up and spraying with the Harbor FreightHVLP gun 38308 and the 43430 Pressure AdjustmentOpen your compressor regulator up so there is plenty of air pressure in the line to the gun I set mine to about 90 psi.

Each time you increase the pressure the pattern will get wider and the dots at the edges of the pattern will get smaller. HVLP stands for high-volume low-pressure Unlike most paint sprayers HVLP guns do not use high pressures to atomize paints. Use your fan-control knob located on top of your sprayer for this setting. The paint technical data sheets usually give the recommended pressure at the gun. I spray with either a Binks or Devilbiss cup gun HVLP and I normally have the pressure set around 60 coming out of my filters and regulator in the spray room. This changes how far the fluid needle can be pulled back ultimately controlling how. This may result in wastage of material and you will be compromising on the durability of the paint system as well.

Post a Comment for "Hvlp Spray Gun Air Pressure Setting"