Air Dryer Compressor System

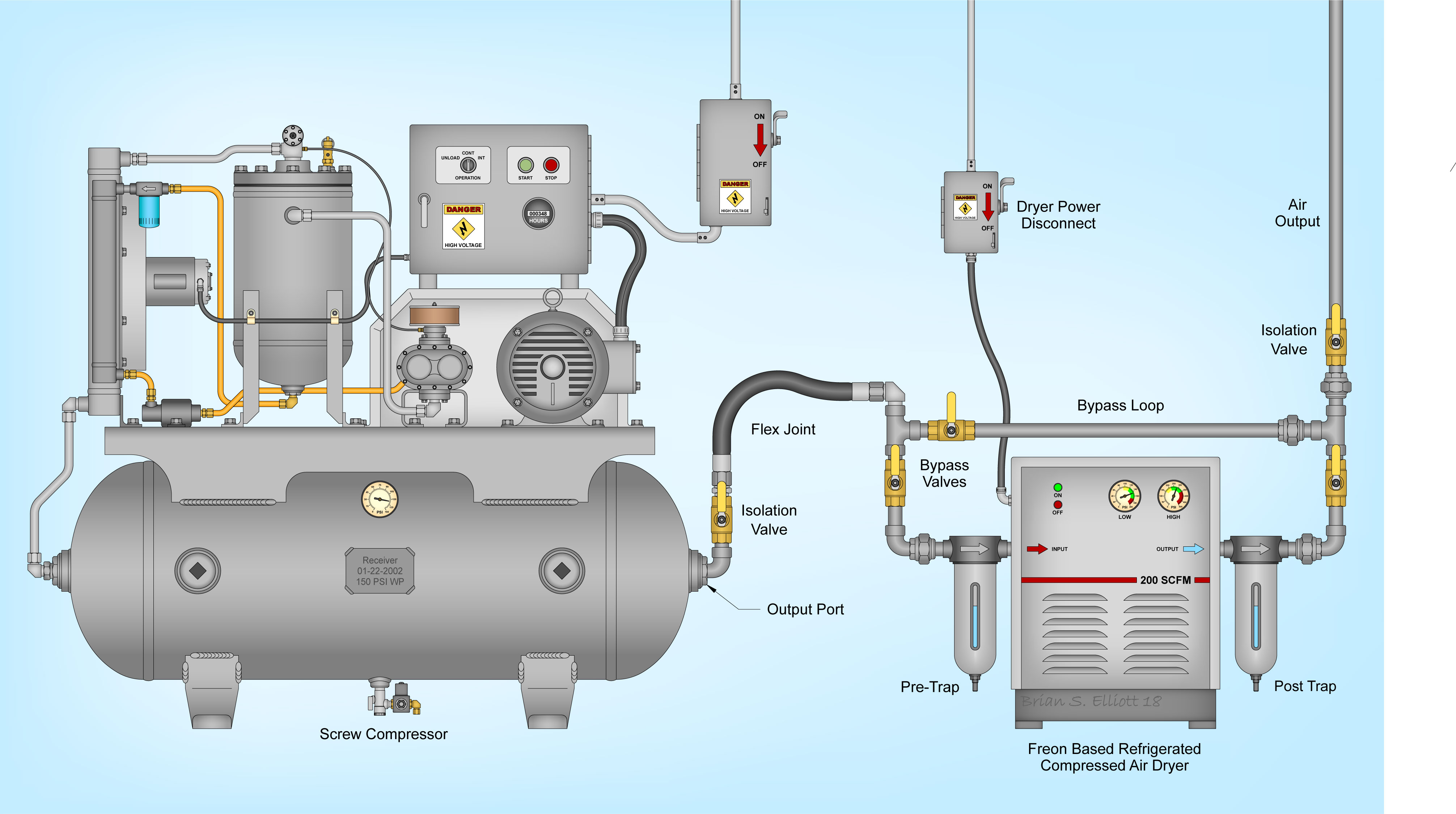

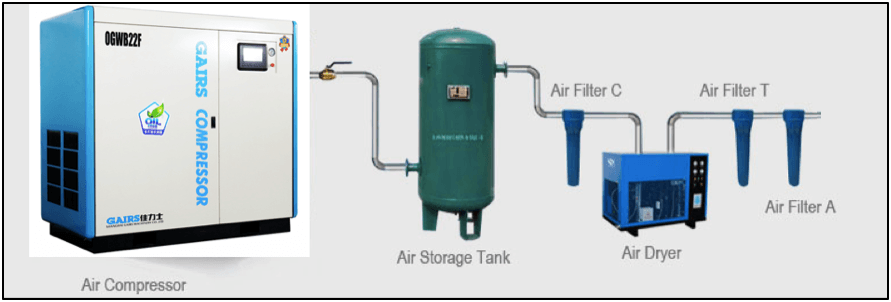

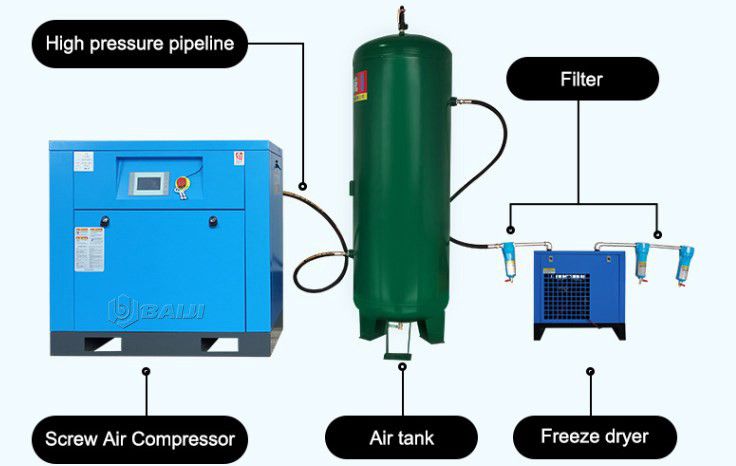

Air dryer compressor system. All Compressed Air Systems Line of air dryers are simple to operate and install like our compressors. This water vapor must be condensed and removed from the air system. But if a circuit requires further treatment air dryers are a must.

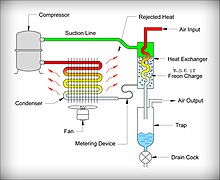

This can eventually lead to a system breakdown costing you time and money. Optimally designed refrigerated dryers can produce air with dew points to approximately 36F 2C. Since some water vapor is left in the air these dryers should not be used in water sensitive applications.

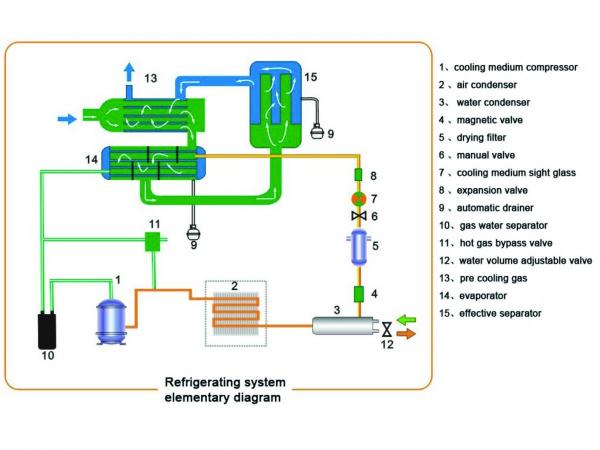

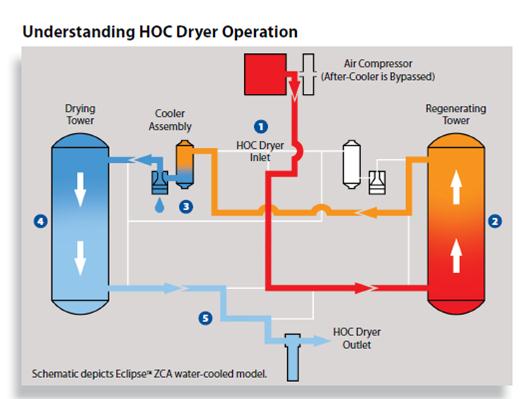

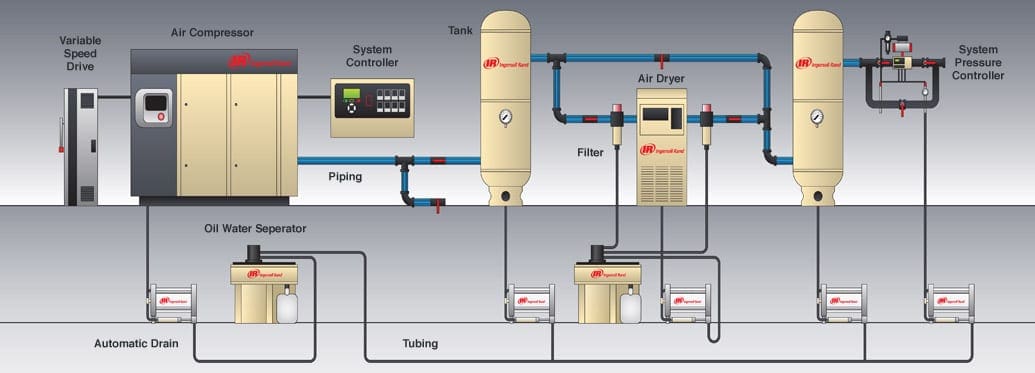

The mills air compressor cooling system was designed to cool the existing centrifugal air compressors and the new Motivair water-cooled 12000 SCFM refrigeration air dryer plus planned compressor growth for the next several years. Mark compressor has a range of compressed air dryer solutions to choose from including refrigerant dryer and desiccant dryers. Many desiccants compressed air dryers incorporate systems that allow the desiccant material to be dried or regenerated automatically by the system.

Our products provide air purification from -40F PDP down to -100F PDP. Thus air dryers are often needed to mitigate water issues. Once aftercoolers and separators have removed the bulk of the water they remove any remaining moisture in your air line.

Of water per day. These dryers are built and designed to provide the smallest footprint possible while ensuring maximum performance. Ensuring that you have the right pressure dew point in your compressed air installation is critical to ensure your products quality and protect your piping system and end equipment.

A compressed air dryer is a piece of equipment designed to separate water vapor or moisture de-humidify from industrial process air. Ad Confira Nossa Linha de Compressores e Torne a Pintura da Sua Casa Em Uma Tarefa Simples. Dryer final selection should be done by a professional.

It is important that there isnt any water in your compressed air since water getting into your process equipment or onto your end product will damage both often with disastrous results. Sem comissão para comprador vendedor.

Ambient air entering an air compressor always contains water vapor.

Basically this means that you have to run your compressor at a higher pressure. Quincy desiccant dryers have ASME and CRN designed pressure vessels standard. All Compressed Air Systems Line of air dryers are simple to operate and install like our compressors. Encontre já a máquina certa. Emax Air dryers are UL-CSA approved scroll compressor electric system for high efficiency and durability. The dryer was not performing to standard. Untreated air can cause corrosion and damage to your pipework and the internal structure of your air compressor. It is important that there isnt any water in your compressed air since water getting into your process equipment or onto your end product will damage both often with disastrous results. Quincy Compressor manufactures a full line of desiccant air dryer systems.

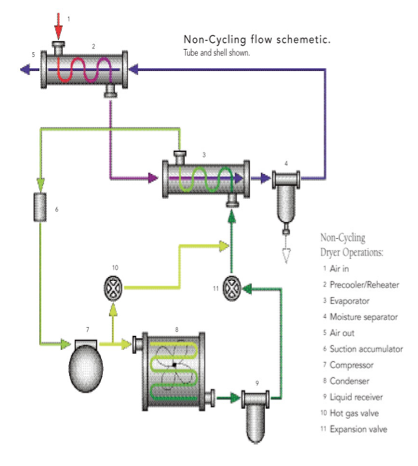

Secondly if you opt to buy a desiccant compressed air dryer check the way that the desiccant is re-generated. Get dry compressed air in high-pressure systems these dryers have a maximum pressure rating of 300 psi. Ambient air entering an air compressor always contains water vapor. In a typical system air flows from the compressor to an aftercooler that lowers the temperature causes condensation and removes the majority of water. At 75 F and 75 relative humidity a 25-hp compressor will produce 20 gal. The mills air compressor cooling system was designed to cool the existing centrifugal air compressors and the new Motivair water-cooled 12000 SCFM refrigeration air dryer plus planned compressor growth for the next several years. This of course will result in more energy consumption by your compressor.

Post a Comment for "Air Dryer Compressor System"